Alfalfa Rotary Dryer

Daily Capacity : 33.6-247t/d

Final Moisture : 12%-15% (adjustable)

Material : alfalfa, grass, etc

- Get Price

-

Welcome to visit the factory at anytime!

Daily Capacity : 33.6-247t/d

Final Moisture : 12%-15% (adjustable)

Material : alfalfa, grass, etc

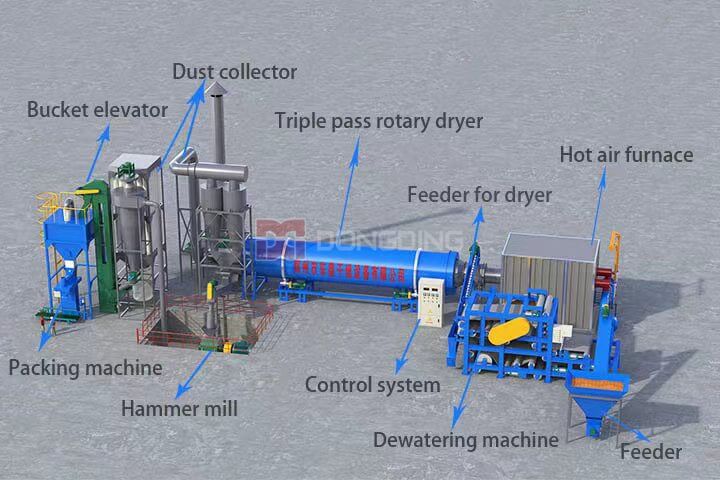

Alfalfa (forage grass) has high nutritional value and is suitable for animal feed. However, the water content of alfalfa is extremely high and it is not suitable for storage. The new type triple pass rotary drum dryer is usually used for drying kinds of forage grass. It can dry the forage grass from moisture content of 65-50% to aboout 10% at one time, and is suitable for dying the grey elephants, alfalfa grass ( lucerne ), pasture grass, foxtail, seaweed, etc. Compared with the traditional dryer, the floor space has been reduced, and the drying efficiency has been improved.

The full alfalfa dryer system is as followed: if the moisture of the alfalfa is higher than 75%-80%, then a screw dewatering machine is needed to reduce the moisture content to 50-65%, which will reduce the load on the rotary dryer and allow the use of a smaller dryer, thus saving on drying costs. And the final moisture of the forge alfalfa after drying can reach 10% or less. The dried forage grass retains the nutrition,bright color, fragrant smell of the alfalfa grass.

We can provide full set of forage alfalfa dryer plant, which includes heating part, feeding machine, dewatering machine, crushing machine, rotary dryer, discharging machine and cyclone dust collector, etc. We can also offer the full Drying and Pelleting Plant in order to make a one-stop solution for our customers.

With a moisture content of 45-75%, the crushed forage is fed into the rotary drum by a conveyor for concurrent-flow drying. Inside the drum, the forage is repeatedly lifted and scattered by the inner-layer lifting flights, moving in a spiral pattern through the inner, middle, and outer layers. This ensures full contact between the forage and the hot air, achieving effective drying. The dried forage is quickly carried through and discharged from the drum by the airflow.

Undried wet forage, due to its own weight, cannot move as quickly. It remains within the controlled travel path for sufficient drying until the moisture content is reduced to the required 12% (as specified by the customer), completing the drying process. The dried forage is then discharged via a screw conveyor.

Besides the drum is equipped with specialized breaking and cleaning devices to prevent uneven drying and avoid charring or scorching of the forage grass.

1.Compared with the single pass rotary drum dryer, the length of the triple pass rotary drum is shortened by 50%, reducing the building area and power consumption is reduced by 60%, saving about 40% project investment.

2. Multiple heating source can be chosen; like disel, natural gas, coal,wood,sawdust,natural gas, etc.

3. The system has good sealing performance and is equipped with a complete dust removal device to prevent dust spillage.

4. The entire alfalfa drying system adopts centralized electrical control, with high automation and easy operation.

5. It can be equipped with follow-up sections such as crushing, mixing, granulating, baling, briquetting, etc. To improve the deep processing level of alfalfa.

6.the final product: the green color and the nutrients of the alfalfa are remained, and have the good taste, which not only enhances the appetite of livestock, but also improves the economic benefits.

Alfalfa Rotary Drying Cases

| Device Specification | DDJG1210 | DDJG1410 | DDJG1610 | DDJG2010/3 | DDJG2210/3 | DDJG2510/3 | DDJG2512/3 | DDJG2912/3 |

| Daily Processing Capacity(t/d) | 33.6 | 40.8 | 58.9 | 131.4 | 145.0 | 167.7 | 204.0 | 247.0 |

| Daily Output(t/d) | 15.6 | 19.2 | 27.7 | 61.8 | 68.2 | 78.9 | 96.0 | 116.2 |

| Water Evaporation Capacity (t/h) | 0.75 | 0.90 | 1.30 | 2.90 | 3.20 | 3.70 | 4.50 | 5.45 |

| Raw Material Water Content(%) | 60-80 | |||||||

| Dried Material Water Content(%) | 12-15(adjustable) | |||||||

| Drying Temperature(℃) | 350-550 | |||||||

| Total Weight(kg) | 32 | 40 | 55 | 95 | 100 | 125 | 145 | 165 |

| Plant Area(㎡) | 15000 | 17000 | 21500 | 26500 | 28500 | 370000 | 41000 | 45500 |

| Device Specification(m) | 5*14 | 5*14 | 6*16 | 8*16 | 8*16 | 10*16 | 10*18 | 10*20 |

we can also provide customized models according to your needs

Brewery Spent Grain Dryer

Alfalfa Rotary Dryer

Yeast Dryer

Pomace Dryer

Our factory is located in Zhengzhou City, Henan Province, and there are 5000 square meters of standardized industrial workshop. The number of staffs is more than 500, together we are dedicated to the R & D and production, installation, after-sales service and technical consultation of the drying equipment.

We have strict quality control system and full set of service. Our products have been exported to over 120 countries such as Indonesia, the Philippines, Vietnam, Thailand, India, Kenya, Nigeria, Romania and many other countries and regions, totally 600+ drying cases all over the world. We are here to provide better products and service for you.

We have strict quality control system and full set of service. Our products have been exported to over 120 countries such as Indonesia, the Philippines, Vietnam, Thailand, India, Kenya, Nigeria, Romania and many other countries and regions, totally 600+ drying cases all over the world. We are here to provide better products and service for you.

Consult to Get Price

NEED A SOLUTION? USE THE FORM TO GET IN TOUCH!

Email : dongding@zzddjt.com

Email : dongding@zzddjt.com