Pomace Dryer

Daily Capacity : 30-247T/D

Final Moisture : 12% (adjustable)

Material : apple residue ,oliver pomace, pineapple residue , citrus residue, tangerine peel, tomato pomace, etc.

- Get Price

-

Welcome to visit the factory at anytime!

Daily Capacity : 30-247T/D

Final Moisture : 12% (adjustable)

Material : apple residue ,oliver pomace, pineapple residue , citrus residue, tangerine peel, tomato pomace, etc.

Pomace has a high moisture and is difficult to store and transport. After been dried, the pomace can be used for animal feed, paper making, biofuel, etc. The pomace dryer from us can quickly dry the wet pomace with a moisture of 80% to a dried product with a moisture less than 12%. The pomace dryer process is as followed; firstly, crush (if needed); then, dewatering ( if the moisture of wet pomace is higher than 75-65%, the screw dehydrator will be needed to reduce the moisture to 65-50%), finally going into pomace dryer.

Due to high moisture, high sugar content and easy adhesion of pomace, special scattering and lifting device device is used inner the dryer to avoid the pomace from sticking to the wall.

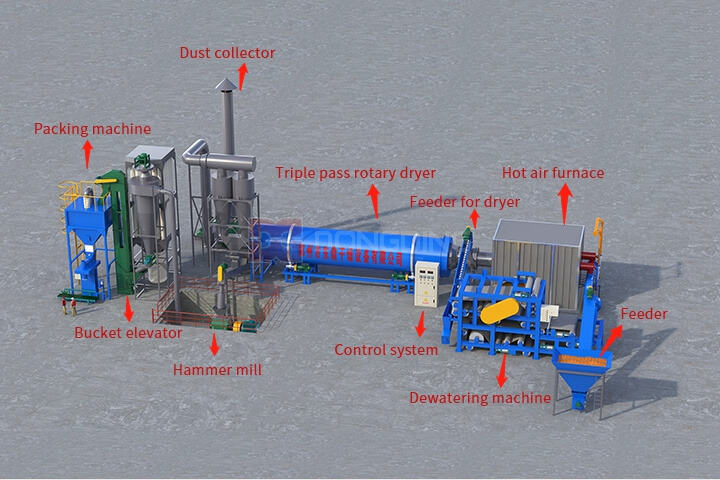

The full pomace dryer system includes heating part, feeding machine, crushing machine, rotary dryer, discharging machine and cyclone dust collector,etc,. Wet fruit pomace is evenly fed into the rotary drum through the feeding system. Under the dual action of hot air (either co-current or counter-current) and the rotation of the drum, the material is continuously lifted and dispersed by the lifting plates, allowing it to fully contact the high-temperature hot air, resulting in rapid evaporation of moisture. The dried pomace is discharged from the outlet, and the waste gas is released after dust removal and purification.

and this pomace dryer production plant is suitable for drying apple residue , pineapple residue , citrus residue, tangerine peel, tomato pomace, etc. It can also used to dry brewery spent grain, sugarcane bagasse, cassava residue, etc

1. Compared with single rotary dryer, length of the three pass pomace dryer is shortened by 50%, reducing the building area and project investment saved about 40%;

2. PLC intelligent control system is adopted, which with high degree of automation and easy operation. Only 1 or 2 people can operate the drying system, labor saving;

3. Use frequency conversion to control material flow, the drying capacity and moisture can be easily adjusted according to the needs of users;

4. The full pomace dryer system is well sealed, and it is equipped with a complete dust removal device, without dust overflow; energy saving and environmental protection.

| Device Specification | DDJG1210 | DDJG1410 | DDJG1610 | DDJG2010/3 | DDJG2210/3 | DDJG2510/3 | DDJG2512/3 | DDJG2912/3 |

| Daily Processing Capacity(t/d) | 33.6 | 40.8 | 58.9 | 131.4 | 145.0 | 167.7 | 204.0 | 247.0 |

| Daily Output(t/d) | 15.6 | 19.2 | 27.7 | 61.8 | 68.2 | 78.9 | 96.0 | 116.2 |

| Water Evaporation Capacity (t/h) | 0.75 | 0.90 | 1.30 | 2.90 | 3.20 | 3.70 | 4.50 | 5.45 |

| Raw Material Water Content(%) | 60-80 | |||||||

| Dried Material Water Content(%) | 12-15(adjustable) | |||||||

| Drying Temperature(℃) | 350-550 | |||||||

| Total Weight(kg) | 32 | 40 | 55 | 95 | 100 | 125 | 145 | 165 |

| Plant Area(㎡) | 15000 | 17000 | 21500 | 26500 | 28500 | 370000 | 41000 | 45500 |

| Device Specification(m) | 5*14 | 5*14 | 6*16 | 8*16 | 8*16 | 10*16 | 10*18 | 10*20 |

Brewery Spent Grain Dryer

Alfalfa Rotary Dryer

Yeast Dryer

Pomace Dryer

Our factory is located in Zhengzhou City, Henan Province, and there are 5000 square meters of standardized industrial workshop. The number of staffs is more than 500, together we are dedicated to the R & D and production, installation, after-sales service and technical consultation of the drying equipment.

We have strict quality control system and full set of service. Our products have been exported to over 120 countries such as Indonesia, the Philippines, Vietnam, Thailand, India, Kenya, Nigeria, Romania and many other countries and regions, totally 600+ drying cases all over the world. We are here to provide better products and service for you.

We have strict quality control system and full set of service. Our products have been exported to over 120 countries such as Indonesia, the Philippines, Vietnam, Thailand, India, Kenya, Nigeria, Romania and many other countries and regions, totally 600+ drying cases all over the world. We are here to provide better products and service for you.

Consult to Get Price

NEED A SOLUTION? USE THE FORM TO GET IN TOUCH!

Email : dongding@zzddjt.com

Email : dongding@zzddjt.com