Mobile Grain Dryer

Daily Capacity : 5-20t/d

Final Moisture :

Material : wheat, maize, corn, rapeseed, millet, kinds of grain and grain seed

- Get Price

-

Welcome to visit the factory at anytime!

Daily Capacity : 5-20t/d

Final Moisture :

Material : wheat, maize, corn, rapeseed, millet, kinds of grain and grain seed

Mobile grain dryers are suitable for solving grain drying problems for small and medium-sized farmers. They do not require fixed locations or extensive auxiliary infrastructure. Their single-batch processing capacity is typically 3–20 tons per day, which meets the needs of small-scale farmers. The mobile dryers are easy to install, maintain, and move, allowing for quick changes in operating locations. The system is also user-friendly and requires no prior knowledge.

Mobile grain dryers can handle staple crops such as rice, wheat, and corn, as well as various other granular crops like rapeseed and millet. They support various fuels, including diesel, straw, rice husk, coal, and even natural gas, meeting the diverse drying needs of different customers. Mobile grain dryers are available in 3t/d, 5t/d, 10t/d, and 20t/d series, allowing customers to choose the model that best suits their needs.

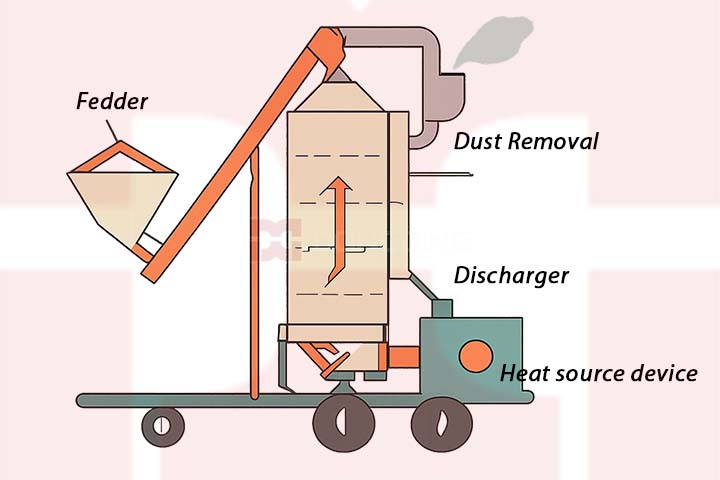

Basic Working Principle

Grain Lifting: A feeder lifts the wet grain to the grain storage section at the top of the dryer.

Air Drying: Clean heated air generated by the heat source is delivered to the dryer by a fan. The wet grain slowly falls through the crisscrossed airflow, with the hot air removing moisture.

Cooling and Discharging: Dried grain passes through a cooling section, where cool ambient air reduces its temperature to near ambient levels. It is then discharged through a discharge mechanism, ready for bagging or loading onto transport vehicles/warehouses.

And flexible heat source options are available, including natural gas, liquefied petroleum gas (LPG), methanol, and bio-oil, etc.

1.Simple Structure, Easy Operation

The mobile grain dryer has a simple structure, is easy to operate, does not require auxiliary equipment, and is easy to transport and move.

2.Uniform Grain Drying, Good Quality

Using heated air as the drying medium and employing a cyclical drying process, the grain is heated and dried uniformly and thoroughly, resulting in good quality after drying. And Equipped with automatic online temperature and humidity measurement devices, significantly improving automation and ensuring even drying.

3.Pollution-Free

Using coal, rice husk, or straw as fuel, which is converted into clean heated air through combustion and heat exchange, resulting in no pollution to the dried grain.

4.Low Investment, Automatic Control, Labor-Saving

Low investment and operating costs, automatic control of the drying process, automatic shutdown, simple and labor-saving operation, suitable for small and medium-sized farms and individual farmers.

5.Easy Cleaning, Suitable for Seed Drying

Easy and thorough cleaning prevents cross-contamination, making it ideal for drying grain seeds.

| Specification | HYDD-5 | HYDD-10 | HYDD-20 |

| Structure type | Batch cycle | Batch cycle | Batch cycle |

| Drying process | Crossflow | Crossflow | Crossflow |

| Proceed capacity per batch | 4.5-6Ton/batch | 9-12Ton/batch | 18-24Ton/batch |

| Moisture reduce speed | 1.8-2.5%/hour | 1.8-2.5%/hour | 1.8-2.5%/hour |

| Effective volume | 8.15M³ | 16.2M³ | 32.6M³ |

| Hot air temperature range | 0-120℃ | 0-120℃ | 0-120℃ |

| Hot air blower air delivery method | Negative pressure | Negative pressure | Negative pressure |

| Total dryer power motor | 10KW | 18.7KW | 37.5KW |

| Heat source heat power (output heat) | 15×10⁴kcal/h | 30×10⁴kcal/h | 60×10⁴kcal/h |

| Heat source option | Gas, oil Coal, wood, biomass pellets | Gas, oil Coal, wood, biomass pellets | Gas, oil Coal, wood, biomass pellets |

Mobile Grain Dryer

Our factory is located in Zhengzhou City, Henan Province, and there are 5000 square meters of standardized industrial workshop. The number of staffs is more than 500, together we are dedicated to the R & D and production, installation, after-sales service and technical consultation of the drying equipment.

We have strict quality control system and full set of service. Our products have been exported to over 120 countries such as Indonesia, the Philippines, Vietnam, Thailand, India, Kenya, Nigeria, Romania and many other countries and regions, totally 600+ drying cases all over the world. We are here to provide better products and service for you.

We have strict quality control system and full set of service. Our products have been exported to over 120 countries such as Indonesia, the Philippines, Vietnam, Thailand, India, Kenya, Nigeria, Romania and many other countries and regions, totally 600+ drying cases all over the world. We are here to provide better products and service for you.

Consult to Get Price

NEED A SOLUTION? USE THE FORM TO GET IN TOUCH!

Email : dongding@zzddjt.com

Email : dongding@zzddjt.com