Coconut Coir Dryer

Daily Capacity : 33.5-247t/d

Final Moisture : <15%

Material : coconut coir, cocopeat, coconut fiber, etc.

- Get Price

-

Welcome to visit the factory at anytime!

Daily Capacity : 33.5-247t/d

Final Moisture : <15%

Material : coconut coir, cocopeat, coconut fiber, etc.

Coconut coir is a powdery substance between the coconut husk fibers. After being dried, the coconut coir can be used in the field of plant cultivation or made into coconut chaff bricks, which has high economic benefits.

The coco coir drying system has the advantages of energy saving and low consumption technology. Through precisely temperature control and scientific sealing technology, the production process is safe, efficient, clean and environmentally friendly.

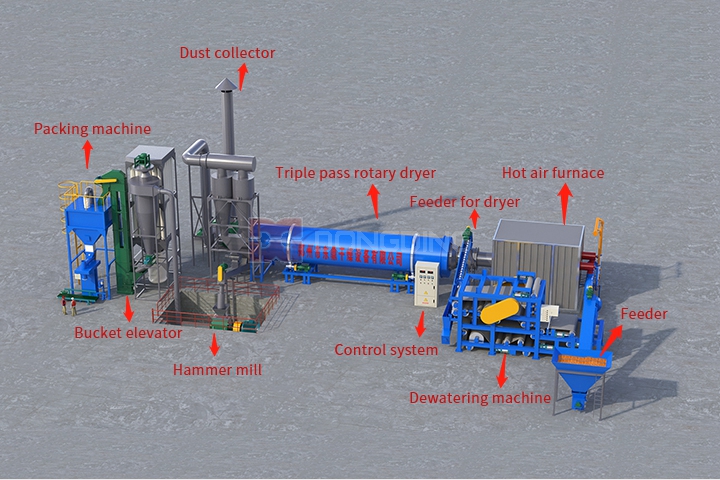

Firstly, coconut coir is dehydrated by dehydrator machine (if high water content), then transported to the rotary drum dryer by the belt conveyor. Because of the inclination of drum dryer, material with hot air moves to the end of dryer body, during which process wet material gets fully contact with the hot air. After drying, most of the dry material is discharged through the belt conveyor. The left material mixed with dust continue goes into the cyclone dust collector and the bag dust collector in sequence, where the dust will be collected. Lastly, with the function of induced draft fan, the left material will discharged through the conveyor.

1. Automatic control ensures that the drying process is even and stable.

2. Designed Inner Structure for coco peat. High drying efficiency to 90-95%.

3. Customized Solution. According to the properties of required parameters to change the operating parameters.

4. Designed Lifting Board. Various material use various combinations of circumferential lifting.

5. The system is equipped with PLC system and video monitoring system, with a high degree of automation and simple operation.

6. Multiple Heating Source. Customers can choose the heating source according their situation, we can design the customized solutions.

| Device Specification | DDJG1210 | DDJG1410 | DDJG1610 | DDJG2010/3 | DDJG2210/3 | DDJG2510/3 | DDJG2512/3 | DDJG2912/3 |

| Daily Processing Capacity(t/d) | 33.6 | 40.8 | 58.9 | 131.4 | 145.0 | 167.7 | 204.0 | 247.0 |

| Daily Output(t/d) | 15.6 | 19.2 | 27.7 | 61.8 | 68.2 | 78.9 | 96.0 | 116.2 |

| Water Evaporation Capacity (t/h) | 0.75 | 0.90 | 1.30 | 2.90 | 3.20 | 3.70 | 4.50 | 5.45 |

| Raw Material Water Content(%) | 60-80 | |||||||

| Dried Material Water Content(%) | 12-15(adjustable) | |||||||

| Drying Temperature(℃) | 350-550 | |||||||

| Total Weight(kg) | 32 | 40 | 55 | 95 | 100 | 125 | 145 | 165 |

| Plant Area(㎡) | 15000 | 17000 | 21500 | 26500 | 28500 | 370000 | 41000 | 45500 |

| Device Specification(m) | 5*14 | 5*14 | 6*16 | 8*16 | 8*16 | 10*16 | 10*18 | 10*20 |

we can also provide customized models according to your needs

Coco Peat Dryer

Coconut Fiber Dryer

Coconut Coir Dryer

Coconut palm coir Dryer

Our factory is located in Zhengzhou City, Henan Province, and there are 5000 square meters of standardized industrial workshop. The number of staffs is more than 500, together we are dedicated to the R & D and production, installation, after-sales service and technical consultation of the drying equipment.

We have strict quality control system and full set of service. Our products have been exported to over 120 countries such as Indonesia, the Philippines, Vietnam, Thailand, India, Kenya, Nigeria, Romania and many other countries and regions, totally 600+ drying cases all over the world. We are here to provide better products and service for you.

We have strict quality control system and full set of service. Our products have been exported to over 120 countries such as Indonesia, the Philippines, Vietnam, Thailand, India, Kenya, Nigeria, Romania and many other countries and regions, totally 600+ drying cases all over the world. We are here to provide better products and service for you.

Consult to Get Price

NEED A SOLUTION? USE THE FORM TO GET IN TOUCH!

Email : dongding@zzddjt.com

Email : dongding@zzddjt.com