Coconut palm coir Dryer

Daily Capacity : 33.6-247t/d

Final Moisture : <15%

Material : palm coir, palm fiber, etc

- Get Price

-

Welcome to visit the factory at anytime!

Daily Capacity : 33.6-247t/d

Final Moisture : <15%

Material : palm coir, palm fiber, etc

The powdered material formed after the crushing of the coconut shell possesses good air permeability and water retention as well as slow and natural decomposition, and has a long life cycle. At the same time, it has low storage and transportation costs and is an environmentally friendly product. However, the coconut shell crushed material must maintain a certain amount of moisture during briquetting and storage and transportation. Dongding Machinery has developed a set of integrated equipment for dewatering and drying briquetting of coconut shell crushed material according to processing requirements. This system has the advantages of energy saving and low consumption technology. , Our company through the precise temperature control and scientific sealing technology to achieve a safe and efficient production process, clean and environmentally friendly.

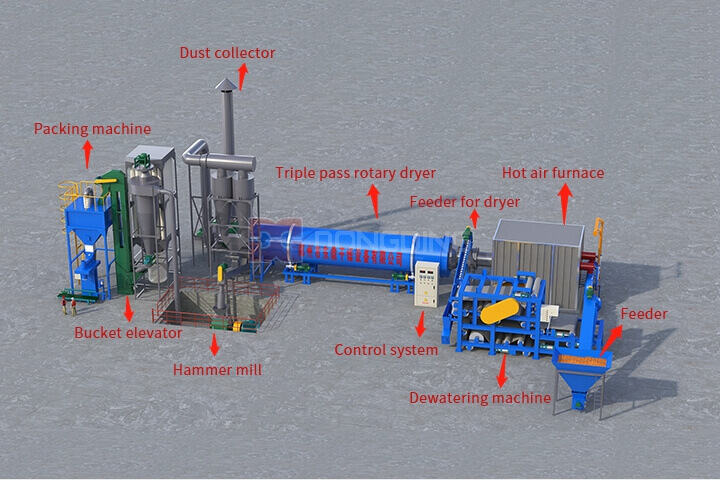

First, the material is Crushed by a crushing machine, and the pulverized material is fed to a screw extrusion dehydrator through a screw conveyor, after which the moisture content can be controlled below 60% (it is not ecessary if the initial moisture is below 60%), then material was sent into the rotary drum by conveyor belt or elecator, when installation, the drum need have a 3-5 degree inclination to ensure the materials move from the upper part to lower parts smoothly, in upper part, there is a birck heating stove or coal gas producer, producing the hot air into dryer, and materials and hot air are contacted completely in the rotary drum, then wet materials are dried. The finished product discharge from the drum and cyclone is sent by the belt conveyor. After the heat exchange, the exhaust gas containing a large amount of water vapor is removed by the cyclone and discharged.

1. Automatic control ensures that the drying process is even and stable.

2. Dryer thermal efficiency up to 70%.

3. The use of tail-end drive makes the transmission more stable and reliable; completely changing the rotation of the support wheel often affects the production phenomenon.

4. The single-layer drum dryer and the three-layer rotary drum dryer can be freely selected according to the site scale.

5. Drying effect is good. Various material use various combinations of circumferential lifting.

6. The required final humidity index can be easily adjusted according to user requirements.

7. The dust removal equipment has a long service life. It can be used for continuous production of the next process.

8. The system can be equipped with various heating source according to the user's requirment.

| Device Specification | DDJG1210 | DDJG1410 | DDJG1610 | DDJG2010/3 | DDJG2210/3 | DDJG2510/3 | DDJG2512/3 | DDJG2912/3 |

| Daily Processing Capacity(t/d) | 33.6 | 40.8 | 58.9 | 131.4 | 145.0 | 167.7 | 204.0 | 247.0 |

| Daily Output(t/d) | 15.6 | 19.2 | 27.7 | 61.8 | 68.2 | 78.9 | 96.0 | 116.2 |

| Water Evaporation Capacity (t/h) | 0.75 | 0.90 | 1.30 | 2.90 | 3.20 | 3.70 | 4.50 | 5.45 |

| Raw Material Water Content(%) | 60-80 | |||||||

| Dried Material Water Content(%) | 12-15(adjustable) | |||||||

| Drying Temperature(℃) | 350-550 | |||||||

| Total Weight(kg) | 32 | 40 | 55 | 95 | 100 | 125 | 145 | 165 |

| Plant Area(㎡) | 15000 | 17000 | 21500 | 26500 | 28500 | 370000 | 41000 | 45500 |

| Device Specification(m) | 5*14 | 5*14 | 6*16 | 8*16 | 8*16 | 10*16 | 10*18 | 10*20 |

we can also provide customized models according to your needs

Coco Peat Dryer

Coconut Fiber Dryer

Coconut Coir Dryer

Coconut palm coir Dryer

Our factory is located in Zhengzhou City, Henan Province, and there are 5000 square meters of standardized industrial workshop. The number of staffs is more than 500, together we are dedicated to the R & D and production, installation, after-sales service and technical consultation of the drying equipment.

We have strict quality control system and full set of service. Our products have been exported to over 120 countries such as Indonesia, the Philippines, Vietnam, Thailand, India, Kenya, Nigeria, Romania and many other countries and regions, totally 600+ drying cases all over the world. We are here to provide better products and service for you.

We have strict quality control system and full set of service. Our products have been exported to over 120 countries such as Indonesia, the Philippines, Vietnam, Thailand, India, Kenya, Nigeria, Romania and many other countries and regions, totally 600+ drying cases all over the world. We are here to provide better products and service for you.

Consult to Get Price

NEED A SOLUTION? USE THE FORM TO GET IN TOUCH!

Email : dongding@zzddjt.com

Email : dongding@zzddjt.com