7 Steps For FELDSPAR PURIFICATION

Time : 2019-09-23 Writer : ddjxThe FELDSPAR PURIFICATION is divided into 7 steps:

► Crushing: Use the Jaw crusher to crush the material stone.

► Slurry washing: delivery the 20-200 mesh powder into the spiral chute, classify and separate the sand from the slurry.

► Classifying: Delivery the separated slurry into the vibrating sieve, to separate the ferric oxide.

► Drying: Removing ferric oxide slurry into rotary drum dryer for the dry feldspar powder.

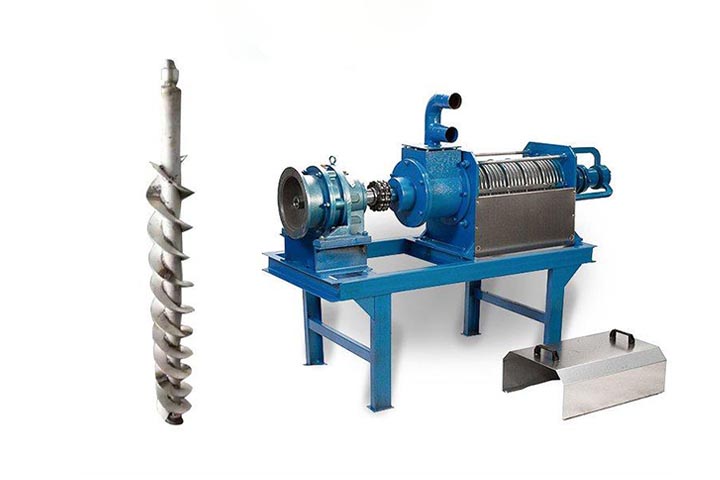

► Iron separating: After drying, dry feldspar powder into 1024 type strong magnetic re-election machine selection, select iron and mica material.

► Purification: After re-election and the general election materials to the high frequency vibration screen, eliminating powder in Fe2O3 and Fe3O4, from potassium feldspar powder;

► Screening: The fine powder of potash feldspar was sent into 20-200 mesh sieve, and the screened product was the finished product with iron content below 0.24%.

Hot Products

Wood Chips Dryer

Sawdust Rotary Drum Dryer

Biomass Dryer

Biomass Pellet Production Line

Biomass Drying Machine

Bagasse Dryer